Siding Insulation - Polyisocyanurate Insulation Sheathing

Enerfoil by IKO is a rigid polyisocyanurate insulation sheathing with a foil facer laminated on the top and bottom side. Manufactured at IKO's state of the art ISO 9001-2008 registered facility, Enerfoil is a sheathing that:

Enerfoil by IKO is a rigid polyisocyanurate insulation sheathing with a foil facer laminated on the top and bottom side. Manufactured at IKO's state of the art ISO 9001-2008 registered facility, Enerfoil is a sheathing that:

- Provides high termal resitance of R6 per inch (RSI 1.05 per 25 mm) for improved energy efficient performance of walls.

- Helps decrease the cost of construction. Designers can reduce the overall footprint of their buildings, as a smaller thickness of Enerfoil achieves the same R-value (RSI) of other types of insulation.

- Is environmentally friendly. No ozone-depleting HCFC's are used in the manufacture of Enerfoil, making it an ideal "Green" product. Enerfoil's Energy Star certification menas that i clearly contributes to reducing energy consumption.

- Is user-friendly. Laminated facers on both sides of the sheathing provide moderate abuse-resistance of the jobsite. Enerfoil is lightweight & easy to cut, thus reducing labor costs on the site. Stud indicators improve accuracy of installation.

- Provides versatility. Foil facings provide the long-term moisture resitance necessary for cavity wall applications. Enerfoil's facings are also compatible with solvent-based materials, which can attach and compromise the performance of the other termoplastic insulations.

- Has a uniform thickness for consitently maintaining air space requirenments in cavity wall applications.

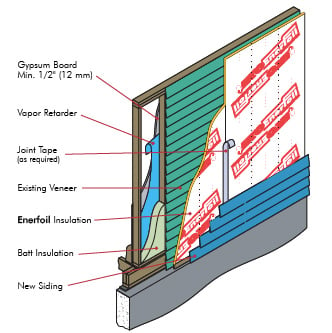

Retrofit Application

Retrofit Application

Corrective action should be taken where evidence of moisture-related problems exist. This may include the replacement or repair of framing members, increased ventilation or installation of a vapor retarder. Install Enerfoil vertically and butt all edges. Secure boards with sashers fasteners and penetrate framing members a minimum of 3/4" (20mm). Install new siding according to manufacturer's instructions.

Effective Thermal Performance

Exterior stud walls are often designed to achieve a nominal thermal resistance value. This methodology, which is based on insulation alone, assumes a consistent rate of heat transfer along the wall. However, framing members typically have a higher rate of heat transfer than the areas in between them. High heat transfer along the studs, or thermal bridging, leads to a lower thermal efficiency for the overall wall assembly. Therefore, it is better to consider the combined effect of the framing materials and insulation in the assembly and calculate the effective R-value (RSI).

Thermal Values

| Thickness | R-Value | Qty./Skid | |

|---|---|---|---|

| mm | inches | ||

| 12 | 0.5 | 3.3 | 90 |

| 18 | 0.75 | 5.0 | 60 |

| 25 | 1.0 | 6.5 | 46 |

| 38 | 1.5 | 9.8 | 30 |

| 50 | 2.0 | 13.0 | 23 |

| 75 | 3.0 | 19.0 | 15 |

|

|

|